Cradle:

The self power craldle with length of 2 Mts by 70cm wide of tubular construction covered with alu. sheets. The cradle will have two electrical hoist with one mounted on each side of the cradle frame. This will have alu. checkered plate flooring. Safety device will be mounted on the cradle above the hoist, this will have electrical control panel for operation of the system. The safe working load of the cradle will be 200 kgs. and suitable for operation by two men carrying cleaning material. Hoisting speed of the cradle will be 8.5m/min.

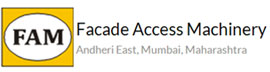

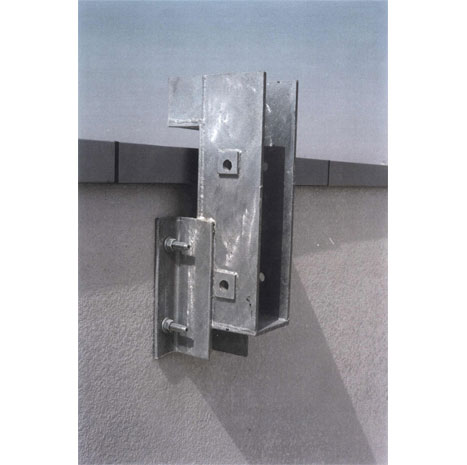

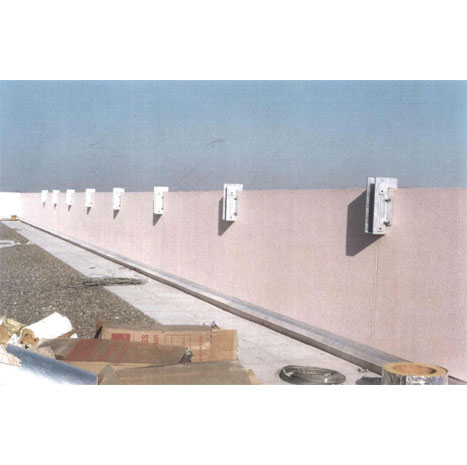

Fixed Brackets

Galvanized Steel Brackets will be permanently anchored to the parapet at areas where cleaning is required. This will have provision for fixing movable arms on which the cradle is suspended.

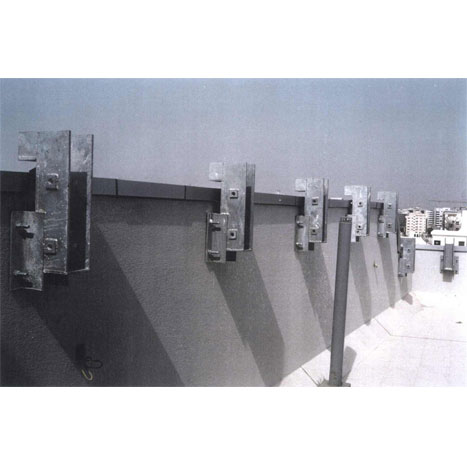

Movable Jib Arms

Movable arms are made of steel hollow section to give it strength and flexibility which can be attached to parapet brackets. The arms will be hot dip galvanized.

Four wire suspension system:

The cradle will be suspended from the roof carriage with 4 wire ropes, two on each side from the two geared trolleys, each one on the two jibs. Two wire ropes will be routed through the hoists for carrying the load and two wire ropes will be through safety devices, which will support the cradle in case of the load, carrying wire ropes or their support fittings fail.

Corrosion Protection:

All structural steel parts are hot dip galvanized, the cradle is painted in any RAL/NCS colour as per the wall cladding.

Control System:

The electric cabinet for operating the maintenance unit is installed inside the cradle and access is easy. Electrical controls for all types of movements are dead man type press buttons.

Every control element is equipped with an emergency stop button and key operated switch.

Control panels are installed in the cradle.

Length of cable is approx.25m. Size 5x2.5mm2 for max.movement of 40m.

Safety Components

- One individual suspension wire rope

- Slack rope switch off

- Control panel inside cradle.

- Key to operate switches at control panels